Grinding Aid Recovery System

Client: Calcit BV

Role: Design & Engineering

Overview

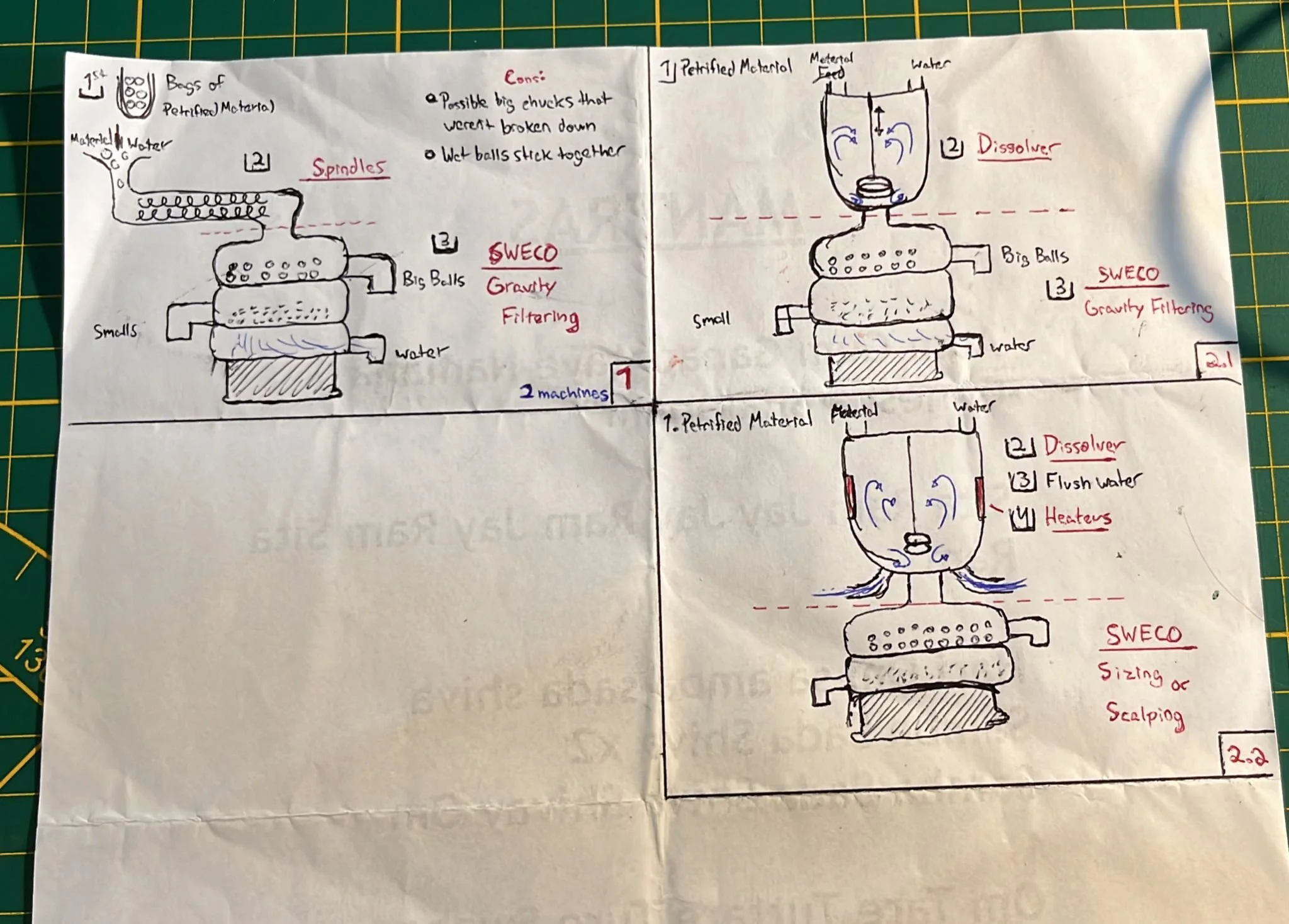

For Calcit BV, I developed an automated grinding aid recovery system for their calcium carbonate mill — specifically designed to recover and separate 6mm and 12mm grinding aid spheres used in the milling process.

Approach

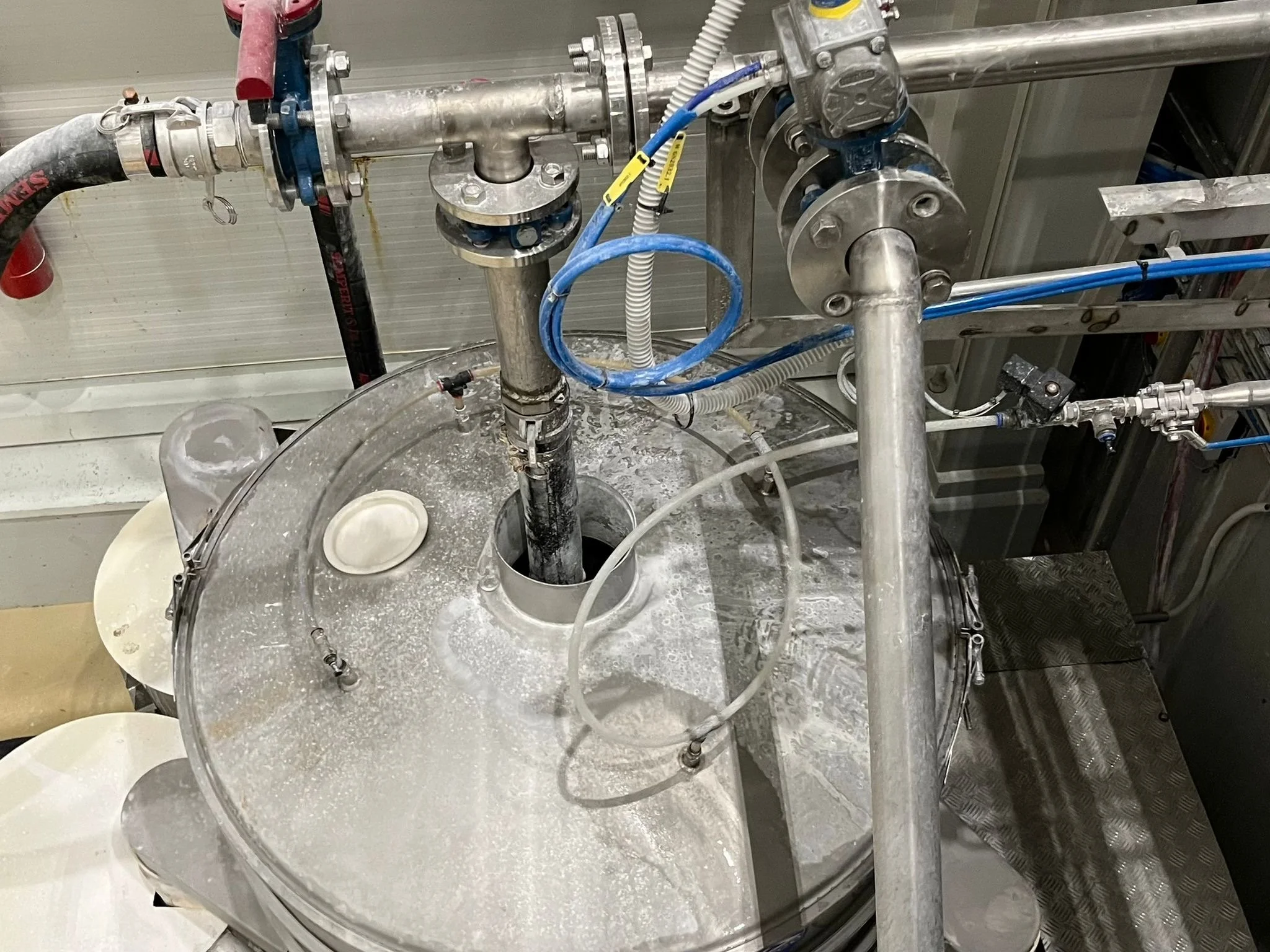

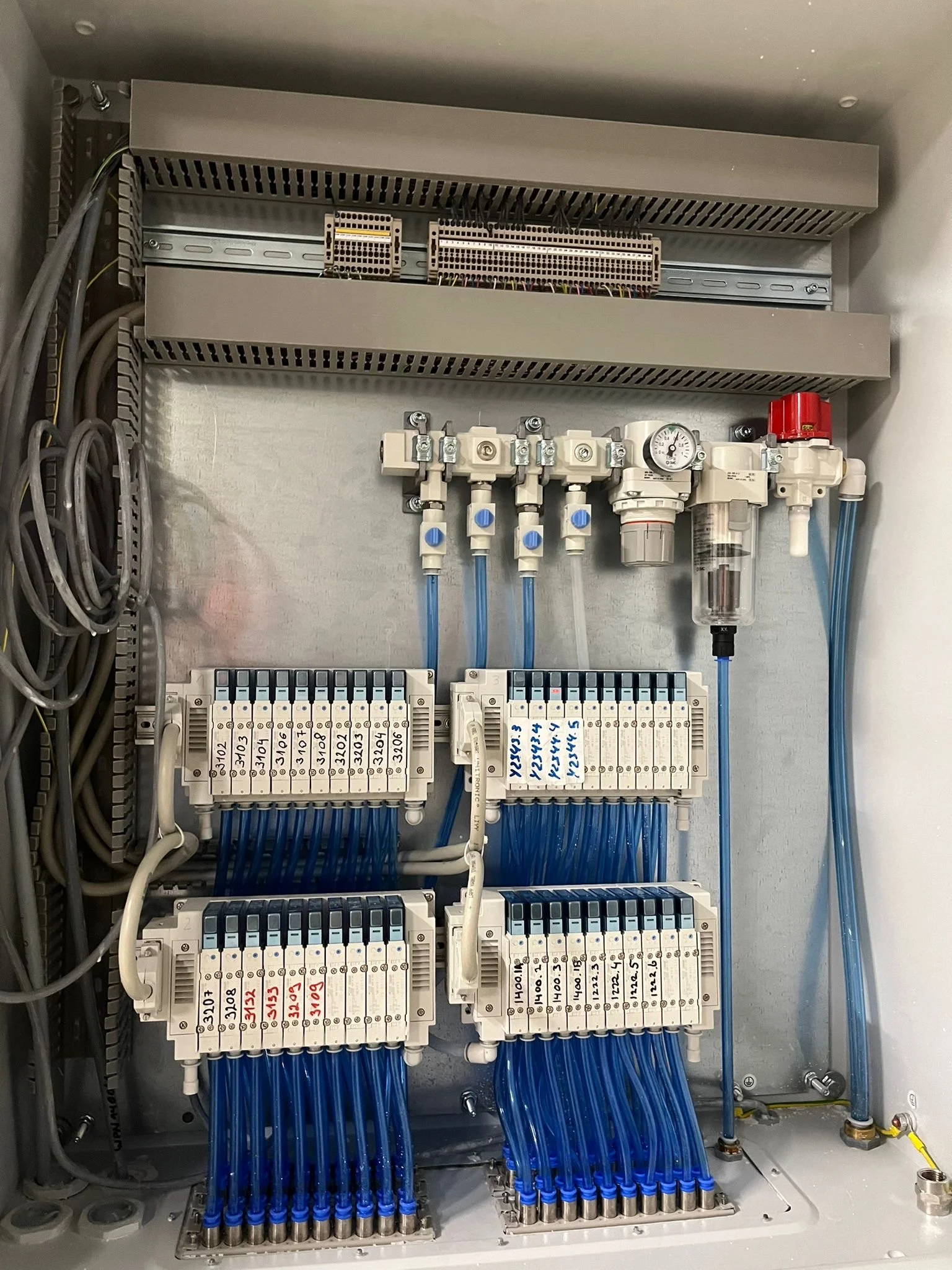

The solution involved a two-stage separation process. First, material was pre-filtered using a JPS coarse separation system. From there, hydropower was used to direct the material into a custom-engineered three-level SWECO machine designed specifically for this application.

Outcome

The final system achieved a projected ROI of just 0.8 years, with estimated savings of €50,000 annually in employee costs and an additional €15,000 annually in electricity. All system planning, quotes, and technical details were completed and delivered, ready for implementation.